.jpg?$responsive$)

At the core: Filtration

Not all filters and machines are created equal. The way they are designed, constructed and sealed determines the filtration performance. Filtration isn’t just about having a good filter – cyclonic technology, filter design, airflow pathways and machine sealing must work side-by-side to expel only clean air. For nearly 30 years, we’ve been fine-tuning our expertise in filtration.

In the context of the COVID-19 pandemic, the air we breathe has never been so in focus. The world over, consumers are looking for a healthier, cleaner home – and quality filtration is central to keeping our homes, workplaces, schools, leisure spaces and public washrooms clean and safe.

-

-

It started with a cyclone…

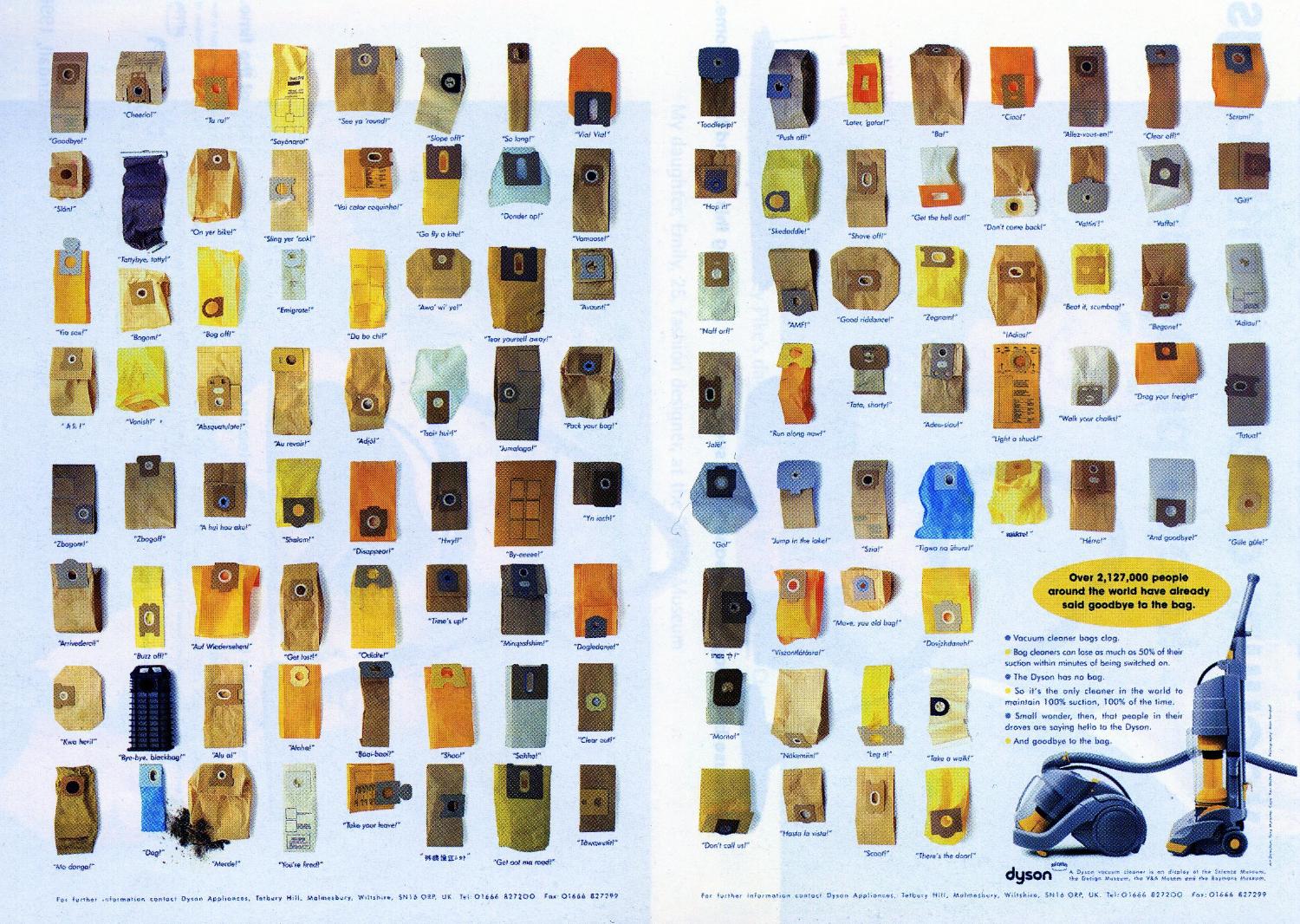

Frustrated by his Hoover Junior clogging on the first pass, James Dyson sought to reinvent the humble vacuum cleaner. 5,127 prototypes later, he had engineered the first bagless vacuum cleaner that never lost suction. Cyclone technology was at the heart of this feat.

A vacuum bag filters air by passing it through a finely perforated bag, trapping the dust in the bag and expelling air. But there are flaws. The holes in the vacuum bag get quickly clogged by dust particles, immediately impacting the suction power. Secondly, the perforations in the vacuum bag are small, but visible. They are far too large to stop ultrafine particles like bacteria or viruses from passing through the bag and being expelled back into the room.

-

Cyclones work by spinning air to separate particles from airflow. Inspired by a similar principle in a nearby sawmill, James Dyson developed the Dyson DC01 vacuum cleaner by replacing the vacuum bag with cyclonic technology. Larger cyclones will generate lower G-force and separate larger fluff and dirt; smaller cyclones spin air faster, generating higher G-force to separate increasingly smaller particles. By developing a multi-stage filtration process with a larger cone – the bin – plus multiple small cones, Dyson engineers created a system that is even more efficient than just one cyclone. The Dyson DC07 vacuum was the first to house multiple cyclones, and our vacuum cleaners today contain the optimal number of cyclones to achieve high-quality dust separation, exerting up to 79,000G per cyclone.

-

…and developed into multi-stage filtration.

Dyson’s latest vacuum technology features our most advanced, multi-stage filtration technologies. The bin is only the first stage, separating out the largest particles that are visible to the naked eye. Next comes Dyson’s multi-cyclone technology. Up to 18 cyclones are configured to provide optimal performance – the diameter of each cyclone is carefully balanced with the space between them, to maintain the velocity required to remove fine dust from the airflow. Although our lightweight and compact models have fewer cyclones, smaller cyclones exert a higher G-force – this is how we can do more with less.

-

-

Pre- and post-motor filters are responsible for filtering the smallest particles, capable of removing 99.97 per cent of particles invisible to the human eye as small as 0.3 microns[1], which could include bacteria and dust mite faeces.

Even in our smallest, most lightweight vacuums, Dyson engineers refuse to compromise on filtration performance – expelling only cleaner air is non-negotiable. Instead of shrinking the filter within the Dyson Micro 1.5Kg cordless vacuum, Dyson engineers worked to miniaturise the bayonet fittings to make room for 1.6 metres of PTFE membrane (filter material) folded 122 times, so that the smaller filter delivers the same advanced filtration as our larger cordless machines.

Always searching for the next problem to solve and with a focus on developing technology for cleaner, healthier spaces, Dyson engineers saw the potential for filtration technologies in other product categories – to tackle airborne pollutants in washrooms, in homes and in commercial spaces.

-

-

Invisible pollution

Inside our homes, workplaces, schools and public washrooms live millions of invisible pollutants. Pollen, pet dander, hair, dust, dust mites, bacteria and viruses are examples of particle pollution. It can be generated indoors, like dust or hair, or can enter from outside, as windows and doors are opened and closed. Similarly, gas pollution is both and indoor and outdoor phenomenon – from NO2 produced by traffic pollution or combustion, from cooking or open fires, to VOCs (Volatile Organic Compounds) from cleaning or personal care products.

-

What is HEPA?

HEPA (High Efficiency Particulate Air) is an air filter efficiency standard – a measure of a filter’s performance. To achieve HEPA performance, filters must meet certain criteria – usually a minimum of 99.95 per cent particle removal at the most penetrating particle size.

The material inside a HEPA filter is usually made of a PTFE or glass-fibre material, arranged as a mat of randomly arranged strands. Depending on the particle size, is it trapped by the HEPA filter in one of three ways:

- Impaction: larger particles collide with and are trapped by the net-like structure of the filter fibres

- Interception: smaller particles try to follow the air and flow around the filter fibres, getting stuck or snagged on the filter material

- Diffusion: particles randomly move when suspended in airflow. Due to Brownian motion, they end up colliding with the fibres and becoming trapped in the filter

Dyson purification and hand drying technologies use HEPA filtration to ensure particles like bacteria, viruses, pollen and dust are removed from the airflow, projecting cleaner air back into the room. Our HEPA filters are tightly pleated to fit more HEPA filter media into a given space, and which increases the surface area available for capturing pollutants.

To address this, ASTM, a world-leading standards institute released a standard to specifically address whole machine HEPA filtration in vacuum cleaners. The new standard demands that not only does the final post-motor filter in a vacuum need to be HEPA-grade, but every single filter and seal throughout the machine has to be HEPA-grade as well.

For those who demand an extra layer of protection, HEPA filtration is included on the Dyson V15 Detect Absolute cordless vacuum. Dyson’s whole-machine HEPA filtration traps 99.97 per cent of microscopic particles as small as 0.1 microns[2] – and expels cleaner air.

-

-

-

Gaseous pollutant capture

Traditionally, filtration relates to removing particles from airflow – the job of a HEPA filter. But Dyson engineers understand the components of indoor air, whether in homes or commercial spaces, and have redefined filtration to respond to all the pollution problems indoors – not just some.

In addition to the HEPA filtration layer, Dyson purifiers use carbon to absorb gaseous pollution. The activated carbon layer, impregnated with a chemical known as Tris, captures gaseous particles including VOCs and oxidising gases such as NO2. Carbon crystals are porous, and like a sponge with water, carbon can absorb gases, odours, domestic fumes and VOCs.

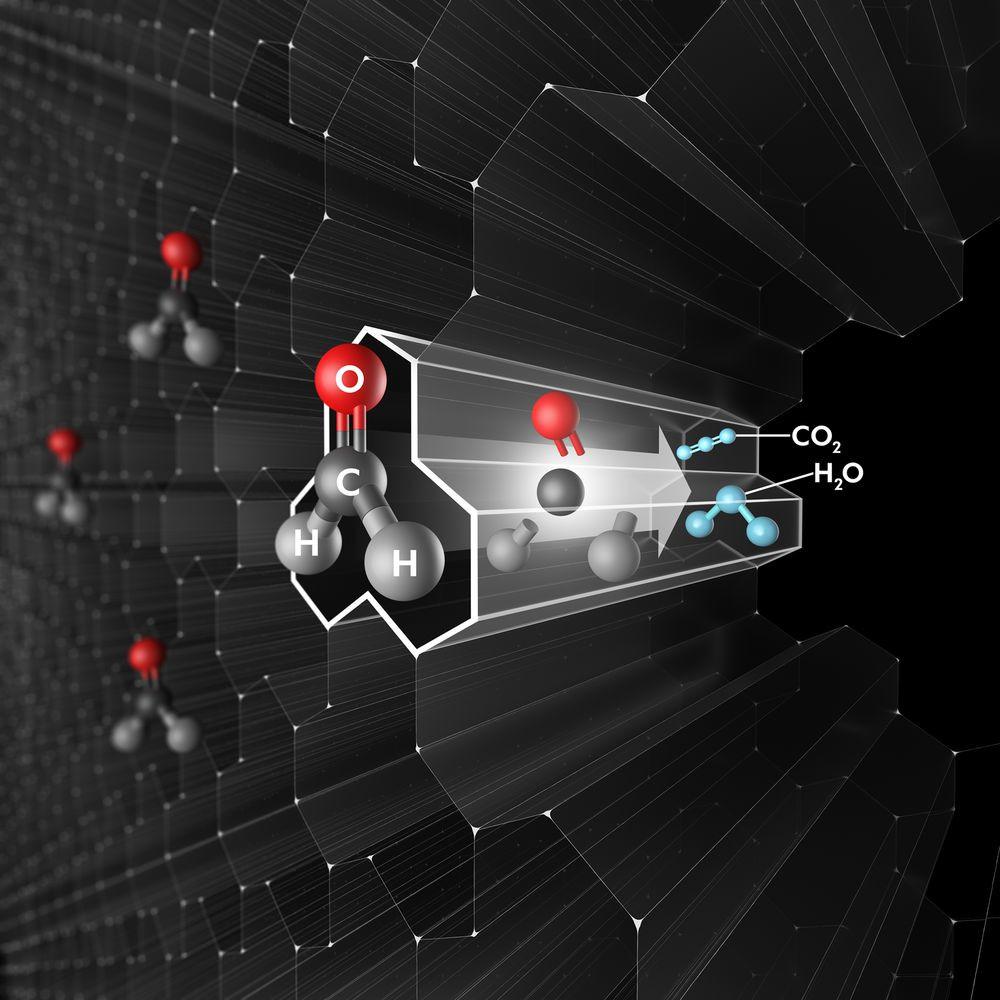

Destroying formaldehyde, continuously

Due to formaldehyde’s continuous release, Dyson engineers had to rethink formaldehyde filtration to find a solution that truly removes the gas from indoor spaces. Dyson’s Selective Catalytic Oxidation (SCO) filter continuously destroys formaldehyde at a molecular level[3]. The filter has a unique coating, with the same structure as the Cryptomelane mineral. Its billions of atom-sized tunnels are the optimal size and shape to interact with the formaldehyde molecules, breaking them down into tiny amounts of water and CO2. It then re-generates with oxygen from the air to keep destroying formaldehyde continuously.

Increasing the layers of filtration can increase the resistance that air passing through the system has to overcome. A lower flow rate would impact the projection of clean air throughout a room – and Dyson engineers refuse to compromise. By careful, tireless iteration, Dyson engineers struck a careful balance, finding the optimum balance of HEPA, carbon and catalytic filter media whilst ensuring the machine could powerfully project clean air to every corner of the room[4].

-

Fully sealed filtration

By testing a filter in isolation, as per industry standard tests, consumers aren’t given the information they need to understand whether a whole product will perform properly in their home. Some of our competitors claim HEPA-certified filtration, because their filters in isolation meet HEPA criteria, even though gaps in their machines allow dirty air to pass through and be expelled into the room.

At Dyson, our engineers have gone a step further in pioneering our own test methods. Working with an external laboratory, they developed a full-machine filtration test that can impartially assess an air purifiers’ whole machine filtration performance. Rather than sealing the filter in isolation into a test chamber, this new methodology places a whole machine in the test chamber, measuring the particulate matter expelled by the purifier following a pollution event.

-

Sealing is critical to ensure that filter efficiency translates into real-world benefit. By sealing the filter into the machine, and ensuring that the airflow pathways are properly sealed, Dyson engineers can be confident that all the air projected out of the machine has passed through the filter, capturing to 99.95 per cent of pollutants as small as 0.1 microns[5]. Fully-sealed filtration isn’t just for purification – it applies to vacuum cleaners and hand dryers too.

In Dyson’s latest purifiers, it’s not just the filter that meets HEPA H13 standard, but the whole machine [6]. Dyson engineers took a forensic approach to achieving a fully sealed machine, creating high pressure seals at an additional 24 critical points. This means our whole machine meets HEPA H13 standard.

-

-

Hair drying, filtered

Filtration is a principle that extends to all Dyson technologies – and haircare is not to be excluded. The burning smell given off by a conventional hair dryer often isn’t hair, but rather dust that passes through the rudimentary filter grill at the back of the machine head and becomes exposed to the heater element. A clogged filter grill can also restrict airflow passing through the machine, impacting performance.

Since its launch, Dyson engineers have reengineered the Dyson Supersonic hair dryer filter for ever-improving performance. Our latest iteration for professional stylists is a new and improved two-part depth loading, maximum efficiency, maximum airflow (MEMA) filter that captures particles as small as 85 microns. The dual-layer filter consists of a hard, outer shell that keeps out the largest particles. The inner layer is a depth-loading filter – the filter media retains particles throughout the material, not just on the surface, giving it a far greater capacity to hold pollutants, and requiring less maintenance.

-

Where we test: filtration labs & spaces

Across our UK, Singapore and Malaysia technology campuses, our experts conduct robust in-house testing on Dyson filtration technologies. Our separation systems laboratories are home to filtration testing and development – measuring filtration metrics as diverse as cyclone efficiency and particle reduction at both component and whole-machine level. Dyson engineers fill our VOC test cubes with toxic cigarette smoke, testing filter performance versus gases like ammonia and acetaldehyde.

When it comes to indoor pollutants, Dyson invested £1million into building the Priestley Lab in Malmesbury, U.K. This state-of-the-art testing facility is equipped with 10 highly sensitive gas detectors which are able to detect 19 different hazardous gases, including formaldehyde and ammonia. To understand pollutants present in air, household dust, and in our machine filters, our dedicated microbiology and household dust labs allow Dyson scientists to get under the skin of indoor pollution – and ensure that Dyson technology works properly in real-world environments.

-

[1] Tested against EN 60312-1 5.11, in boost mode

[2] https://www.atsdr.cdc.gov/formaldehyde/home/index.html

[3] FC035 for HEPA Filtration

[4] 'Third party full machine testing based on GB/T 18801-2018 formaldehyde cumulative clean mass testing with continuous injection until plateau of formaldehyde CADR is achieved. Results may vary in practice.

[5] Tested for air projection (DTM801), purification coverage in a 81m3 room (TM-003711), and heating performance in a 35m3 room (DTM 961).

[6] Tested for filtration efficiency at 0.1 microns (EN1822, ISO29463).

[7] 1 Particle challenge by DEHS oil specified in EN1822 within a chamber specified in ASTM F3150. Tested in Max Mode at IBR US, for whole machine efficiency above 99.95%.

.jpg?$responsive$)