Explore: Hand dryers | Lighting | Air treatment | Vacuum cleaners | Hair care

Dyson purifiers create a cleaner, more comfortable environment for employees, students and guests.

Dyson purifiers remove 99.95% of pollutants as small as 0.1 microns.¹

Dyson business case study

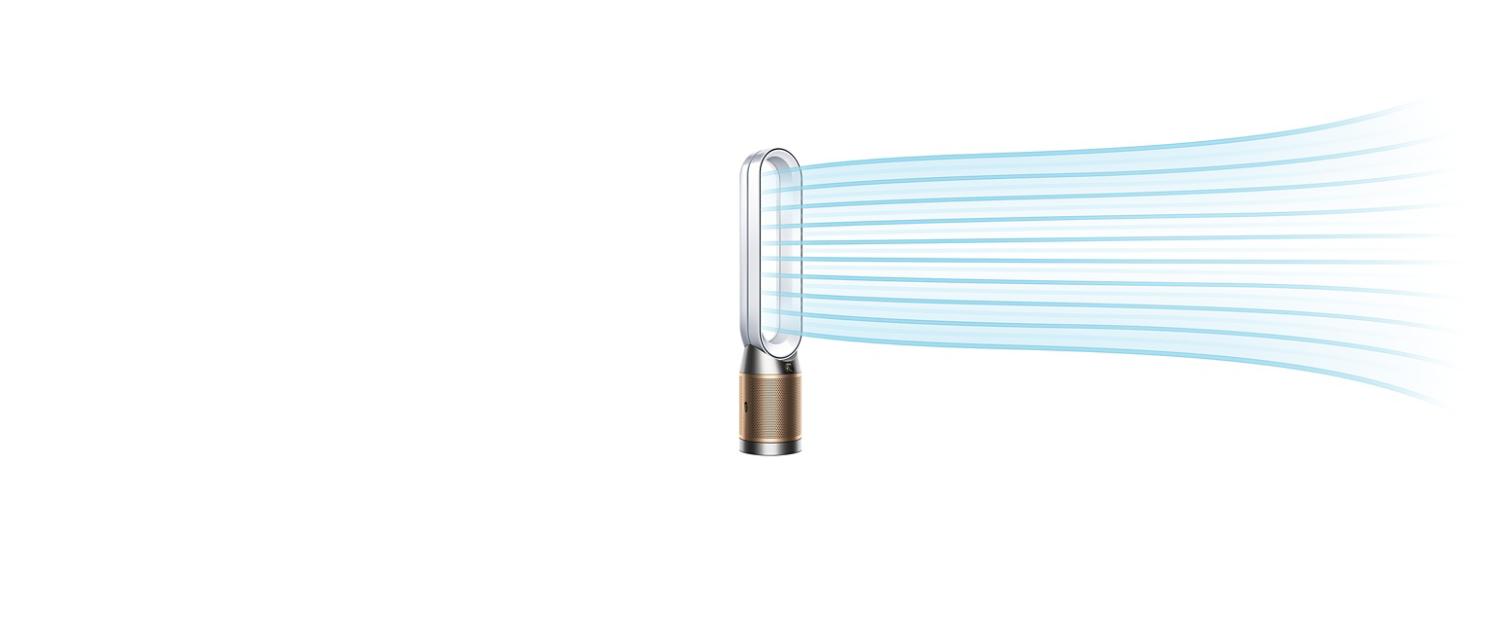

Engineered to purify large spaces, with performance and wellbeing in mind. The Dyson HEPA Big + Quiet Formaldehyde purifying fan creates a cleaner, more comfortable working environment.

- Captures H1N1 virus², bacteria and allergens

- Even destroys formaldehyde³

- Removes 99.95% of pollutants as small as 0.1 microns¹

Pollution can build up indoors

Everyday items in commercial environments, such as furniture and printers, can release potentially harmful pollutants. Our sealed filtration systems help remove them from the air.

Our newest purifier technology detects and destroys formaldehyde, continuously³

Formaldehyde is a volatile gas that can emit over time from the woods and glues found in flooring and furniture. Dyson's latest air purifiers detect and destroy formaldehyde³, as well as remove gases⁴ and 99.95% of pollutants as small as 0.1 microns.¹

Discover other Dyson purifiers in the range. Purifies, heats and cools you.

Automatically senses, captures and traps pollutants for cleaner air. Dyson purifiers are fully sealed to H13 standard⁶, preventing pollutants leaking back into the air. So what goes inside, stays inside.

- 1 Tested for filtration efficiency at 0.1 microns (EN1822, ISO29463).

- 2 Whole machine tested by independent third-party laboratory Airmid (Ireland) in 28.5m³ test chamber pre-conditioned to 20±3C and RH 50±5%. Influenza A (H1N1) aerosolised in the test chamber and airborne concentration observed for the duration of 60 minutes under maximum Fan speed. Achieved 99% efficacy but real life efficacy may differ depending on actual environment and Fan speed. Tested on Influenza A (H1N1) only.

- 3 Third party full machine testing based on GB/T 18801-2018 formaldehyde cumulative clean mass testing with continuous injection until plateau of formaldehyde CADR is achieved. Results may vary in practice.

- 4 Gas capture rates vary.

- 5 Tested for purification coverage in an 81m³ room.

- 6 Particle challenge by DEHS oil specified in EN1822 within a chamber specified in ASTM F3150. Tested in Max Mode at IBR US, for whole machine efficiency above 99.95%.

- 7 Tested for purification coverage in an 81m³ room and heating performance in a 35m³ room.